Electroless nickel and other nickel finishes provide corrosion and wear resistance, appealing aesthetics and adhesion for subsequent processes.

Nickel is a hard metal that is silvery-white in color with strength, ductility and resistance to heat and corrosion. Not many things are made of pure nickel; it is often used in combination with other metals to produce stronger more durable products or as a protective coating for softer metals. It is extremely useful for producing many materials including stainless steel, electronics, machinery, heat exchangers and much more.

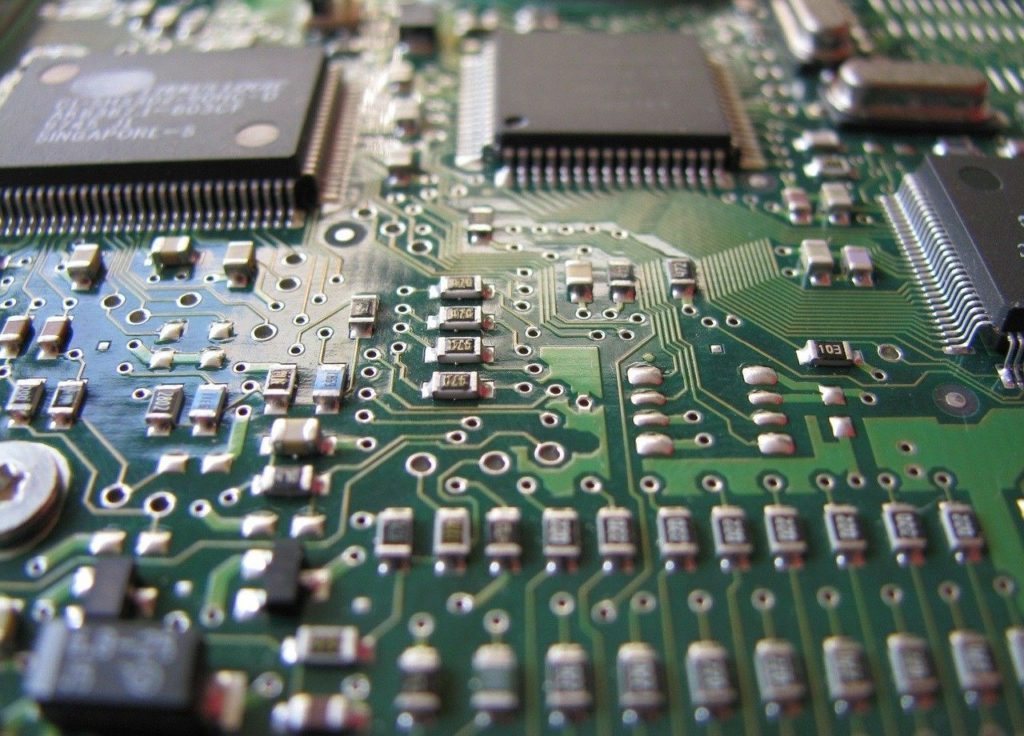

As a coating, nickel is widely used in the automotive, aerospace and electronics industries.

Electroless Nickel Plating

Electroless nickel plating is a highly effective corrosion protection solution for various metals, including steel, copper, and brass. In addition to corrosion protection, electroless nickel can be used to protect against wear and abrasion, and improve hardness, solderability and aesthetics. With electroless nickel, tighter thickness tolerances can be achieved with consistency and reliability for even the most intricately shaped high precision parts. Electroless nickel plating is frequently used as a coating in printed circuit boards for electronics with an added layer of gold to further prevent corrosion and enhance conductivity.

The Electroless Nickel Process

Electroless nickel plating is a chemical process that distributes a uniform layer of nickel-phosphorus on the surface of the metal part. Unlike electroplating, the electroless process uses metal ions in a chemical solution causing an autocatalytic reaction to adhere to the coating and therefore, no electrical current is needed.

Sulfamate Nickel – QQ-N-290 Class 2

Sulfamate nickel is an appropriate finish option for brass, copper and steel components that require both corrosion-resistant protection and an economical restoration to original specifications. Because the coating is 99.9% pure nickel, it is incredibly dense and exceptionally corrosion-resistant. It also increases wear resistance, tensile strength and temperature resistance.

Bright Nickel – QQ-N-290 Class 1

Bright nickel plating can be used to coat various metal substrates including brass, copper alloys, steel and other metal to provide a clean bright finish. The bright reflective finish is a result of its elevated sulfur content. Bright nickel offers good corrosion resistance, and increases surface hardness and conductivity, but is not as ductile or corrosion resistant as other types of nickel plating.

Sulfamate and Bright Nickel Process

Bright nickel and sulfamate nickel are both electroplating processes.

Cleaning the parts to be free of dirt, grease and contaminants are critical steps in the nickel electroplating process. It can involve a combination of masking, heat treating, pickling and etching to further prepare the parts.

Once the part has been prepared, it is immersed in an electrolyte solution and used as the cathode. Nickel is dissolved into the electrolyte to form nickel ions. The nickel ions move through the solution and deposit on the cathode, the surface of the substrate.

AMF Technologies offers electroless nickel MIL- C-26074 and other nickel finishes including Sulfamate Nickel – QQ-N-290 Class 2 and Bright Nickel -QQ-N-290 Class 1.

We can provide a wide variety of finishes to achieve aesthetic and performance characteristics. Please contact us to learn more about our finishing services or to request a quote.