For many applications, the surface finish can significantly affect the performance and durability of the product. Rough surfaces wear more rapidly and have greater friction coefficients that promote adhesion. Conversely, equipment used in pharmaceutical and food processing environments requires smooth surfaces to prevent contamination and corrosion.

Surface finish is a measure of the texture of a product’s surface. It is characterized by surface roughness, surface waviness, and the lay of the surface pattern. Surface roughness is a measure of finely spaced surface irregularities. Waviness is the measurement of the more widely spaced component of surface texture. The Lay is the direction of the predominant surface pattern and is usually a result of the production method used for manufacturing.

Measuring Surface Finish Roughness

While there are several ways of measuring roughness, the Ra arithmetic average roughness system is the most common. Ra is calculated as the Roughness Average of a surface’s measured microscopic peaks and valleys. It measures the arithmetical average deviation of the actual surface from the surface profile mean. It is determined by totaling all the absolute values of all the areas above and below a mean line, divided by the length of a sample. Ra roughness average is the main height as calculated over the entire measured length or area. It is quoted in micrometers or micro-inches. For 2-dimensional computation: (Ra = 1/n * SUM(ABS[Zi-Zmean] from i = 1 to n)

The RMS (Root Means Square) geometric average roughness system is used less frequently but can still be found on older specifications. It uses microscopic peak and valley measurements in a different calculation. The Root Mean Square (RMS) average is the square root of the average height deviations from the mean line divided by the surface squared. (RMS = SQRT[ 1/n* SUM(Zi-Zmean)^2 ] from i=1 to n)

Surface Measuring Tools

A profilometer is a measuring instrument used to measure the surface of a product or part. It is a roughness tester that can be used to determine the surface texture of a material quickly and accurately. It shows the roughness depth (Rz) as well as the mean roughness value (Ra) in micrometers or microns (µm). There is a wide range of instruments for mechanical testing. A contact surface roughness profilometer reads the part’s surface by gliding a stylus over it, this may scratch or mark it. Interferometry or other optical 3D metrology tools can measure the part surface without contacting its and therefore, will not cause damage.

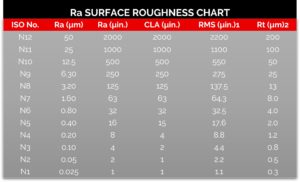

Ra Surface Finish Chart

ISO No = New ISO (Grade) Scale Numbers

Ra = Roughness Average micrometers

Ra = Roughness Average microinches

CLA = Center Line Average microinches

RMS = Root Mean Square microinches

Rt = Roughness Total microns

Got questions about how best to achieve the desired finish? Contact us here, email us or give us a call at 781-982-0137.